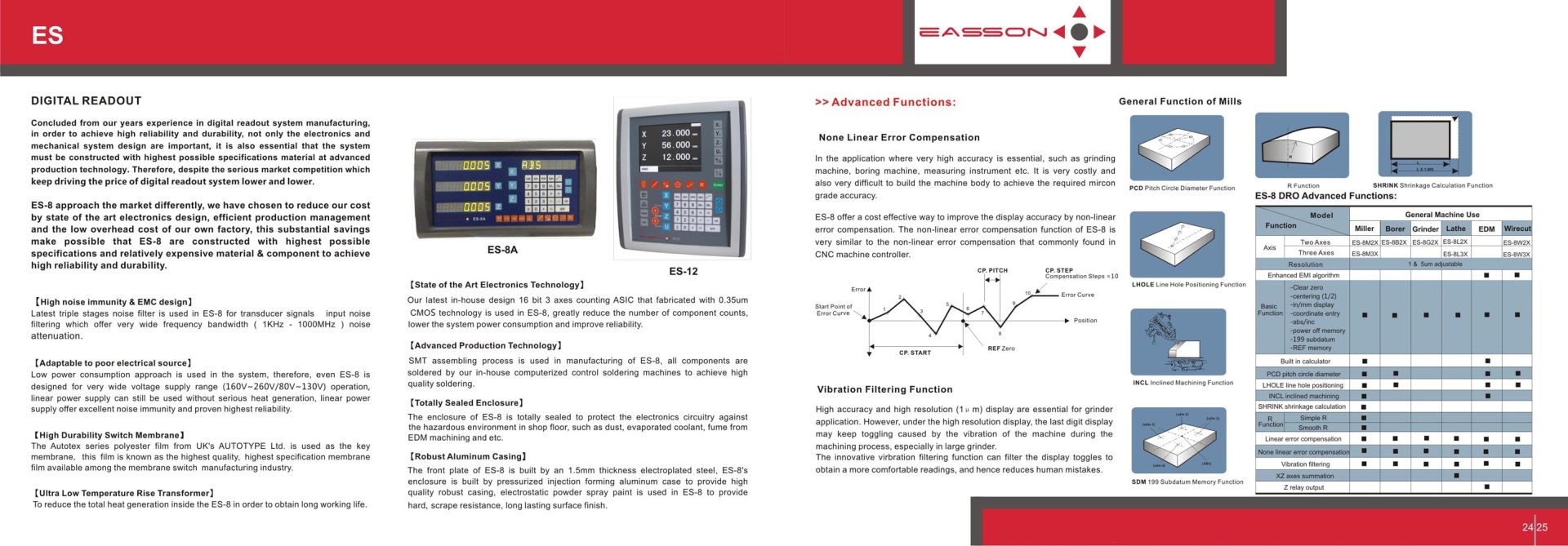

Easson ES-18C LCD digital readout

Easson ES-18C LCD digital readout 2 or 3 axis is a multi-purpose design usable for any machine such as lathe, milling machine,

EDM and grinding machine (Only have to set this once).

Easily create round hole patterns, hole series, radius and much more.

The Easson ES-18C LCD digital readout 2 or 3 axis has a very user friendly operation.

Functions:

- Circular drilling function: drill or mill holes in a circle

- Linear drilling function: drill or mill holes at an angle in a straight line

- Cutting radius correction: when using a cylindrical cutter, the tool radius must be taken into account.

- Determine the center workpiece: simply calculate the center point of a workpiece (1/2 value)

- 199 sets of tool database or date memory (SDM): simple tool offset for the lathe tools or for SDM points at the milling machine

- Radius milling: simply mill a radius

- Function calculator: calculator function can make the operation more efficient

- Slope calculation: enter the two points of the workpiece, the DRO can calculate the slope of the workpiece.

- Preset value: set a value on the display per axis

- Linear error compensation or segmented error compensation: compensation for absolute precision and maximum efficiency.

- segmented compensation can compensate the linear machine deviations.

- Sum of axis: in the Lathe mode you can sum the Z axis and show the total value of the 2 axis in 1 display.